I was looking at Rad Pads...they are 14deg for the rear and 8deg for the front.(?)

I always thought you would want the front to have more wedge than the back has de-wedge.

I want to know what wedges people run for different conditions and all...

I am having wood wedges made from 2.5deg-15deg in 2.5deg increments.

I would like to get an idea of what others are riding so I have a "starting point".

thanks.

p

wedge risers/your preferences???

Moderator: Henry Julier

-

Patio Mendino

- Posts: 59

- Joined: Tue Apr 29, 2003 2:00 am

- Location: over yonder

- Contact:

-

Tom Thompson

- Posts: 230

- Joined: Wed Oct 02, 2002 2:00 am

- Location: Dublin, GA.

P - just noticing your post here...what, 2 weeks after the fact?

There are SO many things to consider when wedging and dewedging trucks.....your stance, the type and speed of the course your running.....the list goes on but those are the most important in my mind.

IMHO, the best way to start is mellow, say 5 degrees added to the front and the same taken away from the back. work it from there. If you've never experimented with wedging before, you'll immediately be able to tell a huge difference in how your setup turns. Also keep some cut-up 1/8" risers on hand and use them to increase or decrease the angles on your trucks as needed. It's all about experimenting and it's different for everyone.....PEACE!

There are SO many things to consider when wedging and dewedging trucks.....your stance, the type and speed of the course your running.....the list goes on but those are the most important in my mind.

IMHO, the best way to start is mellow, say 5 degrees added to the front and the same taken away from the back. work it from there. If you've never experimented with wedging before, you'll immediately be able to tell a huge difference in how your setup turns. Also keep some cut-up 1/8" risers on hand and use them to increase or decrease the angles on your trucks as needed. It's all about experimenting and it's different for everyone.....PEACE!

Like Patio I've noticed just the opposite of the below recommended Rad Pad system that I think Patio is talking about. From what I've seen lately of many of the top skaters using Indy's and RTX trucks, most put the more angled "wedge" up front and go with a much lesser angled "de-wedge" or "flat" in the rear.

====================================

One thing that was pointed out to me the other day by Steve Evans was that as you "wedge" a front truck (thin end of the wedge forward) you are not really raising the axle height much at all as compared with "de-wedging" a truck.

But if you "de-wedge" the back truck (thin end forward) you are raising the axle height much more than "wedging". Even though both raise the axle height "de-wedging" does more so. A bit more than twice as much.

Put a truck on a table and see for yourself, raising either end and see how it makes the axle height higher off the table. For comparison (just an example) a 7/8" "wedge" raises the axle about 1/4" for an RTX, and a 7/8" "de-wedge" raises the axle 9/16". Roughly this would make for a 5/16ths inch more axle height for a back "de-wedge".

So if you were going with the above Rad Pad system(but using the most angled Rad Pad "wedge" up front) and using Avalons for instance you might use the more angled Rad Pad wedge with an additional 1/2" (just a guess) flat riser in the front just to make both axles the same height if you used that less angled wedge in the back as is. But the axle height would only be the same with that Rad Pad system if you added quite a bit of additional rise in the front using that above system, If you were using the more angle wedge up front and the lesser (which has rise built into it) in the rear.

But I would think that having 1/2" under any front wedge would be a little much. Probably 1/8 to 1/4" max would be more appropriate for TURNER Avalons under that more angled Rad Pad wedge in the front. So I say use the more angled wedge up front and toss the lesser one for something else that would keep the axle height the same.

The lesser angled wedge in that Rad Pad system has too much rise built into it if it were to be used as a back de-wedge. This has to be taken into consideration to make the axle heights the same, if that is important to you. I would think that you'd need more clearence and range of turn for the front. With range of turn being most important. And you'd not want your deck angled downward, especially if it was cambered to begin with.

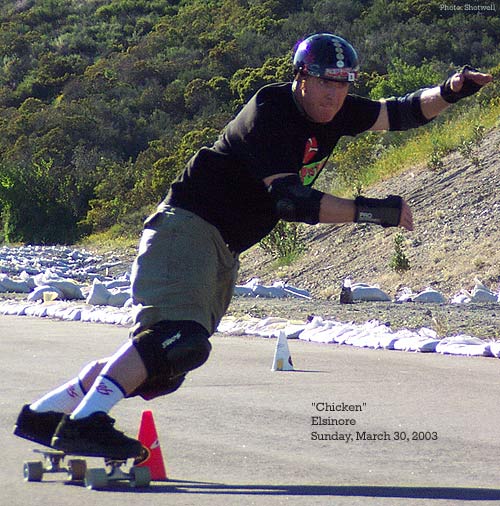

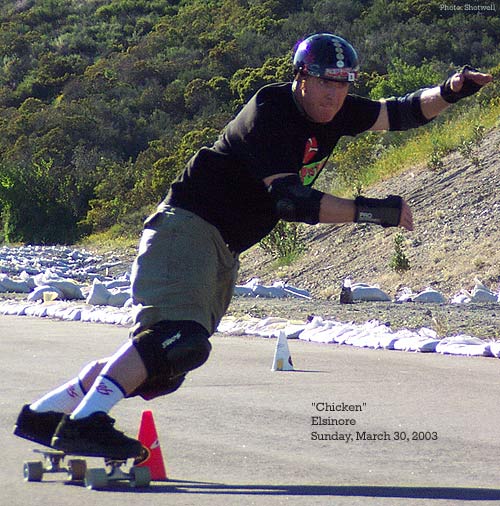

Look at this picture below and you'll see that the front truck is wedged with a good amount of angle, and looks to have additional rise as well, and the back truck looks to have just a flat riser, maybe 3/8" or so. There is also a good amount of clearance between those Avalons and the deck:

Chicken won this Elsinore GS race, with speeds that might have been near 35mph.

Chicken's bushing setup: "I ride soft bones hardcore bushings in the front truck and Medium bones hardcores in the back. They seem to be about the best thing going for Indys."

Maybe certain wedge combinations work differently for different skaters styles or decks, camber, etc, and if your using Indy or Tracker RTX. And the geometry of the truck could change with different size bushings as well. I guess that really the only way to test is with a timer for your particular style of skating, equipment, and the course type and speed your trying to adapt it to.

====================================

One thing that was pointed out to me the other day by Steve Evans was that as you "wedge" a front truck (thin end of the wedge forward) you are not really raising the axle height much at all as compared with "de-wedging" a truck.

But if you "de-wedge" the back truck (thin end forward) you are raising the axle height much more than "wedging". Even though both raise the axle height "de-wedging" does more so. A bit more than twice as much.

Put a truck on a table and see for yourself, raising either end and see how it makes the axle height higher off the table. For comparison (just an example) a 7/8" "wedge" raises the axle about 1/4" for an RTX, and a 7/8" "de-wedge" raises the axle 9/16". Roughly this would make for a 5/16ths inch more axle height for a back "de-wedge".

So if you were going with the above Rad Pad system(but using the most angled Rad Pad "wedge" up front) and using Avalons for instance you might use the more angled Rad Pad wedge with an additional 1/2" (just a guess) flat riser in the front just to make both axles the same height if you used that less angled wedge in the back as is. But the axle height would only be the same with that Rad Pad system if you added quite a bit of additional rise in the front using that above system, If you were using the more angle wedge up front and the lesser (which has rise built into it) in the rear.

But I would think that having 1/2" under any front wedge would be a little much. Probably 1/8 to 1/4" max would be more appropriate for TURNER Avalons under that more angled Rad Pad wedge in the front. So I say use the more angled wedge up front and toss the lesser one for something else that would keep the axle height the same.

The lesser angled wedge in that Rad Pad system has too much rise built into it if it were to be used as a back de-wedge. This has to be taken into consideration to make the axle heights the same, if that is important to you. I would think that you'd need more clearence and range of turn for the front. With range of turn being most important. And you'd not want your deck angled downward, especially if it was cambered to begin with.

Look at this picture below and you'll see that the front truck is wedged with a good amount of angle, and looks to have additional rise as well, and the back truck looks to have just a flat riser, maybe 3/8" or so. There is also a good amount of clearance between those Avalons and the deck:

Chicken won this Elsinore GS race, with speeds that might have been near 35mph.

Chicken's bushing setup: "I ride soft bones hardcore bushings in the front truck and Medium bones hardcores in the back. They seem to be about the best thing going for Indys."

Maybe certain wedge combinations work differently for different skaters styles or decks, camber, etc, and if your using Indy or Tracker RTX. And the geometry of the truck could change with different size bushings as well. I guess that really the only way to test is with a timer for your particular style of skating, equipment, and the course type and speed your trying to adapt it to.

Last edited by Glenn S on Sat Dec 06, 2003 4:58 pm, edited 9 times in total.