3rd Generation ?

Moderator: Gary Fluitt

-

Malcolm Stooke

- Posts: 82

- Joined: Mon Sep 18, 2006 8:47 am

- Location: greater vancouver

-

Adam Winston

- Posts: 202

- Joined: Wed Jan 25, 2006 9:20 pm

- Location: Toronto,Canada

- Contact:

-

Chris Barrett

- Skurfskater

- Posts: 207

- Joined: Thu Feb 17, 2005 5:19 pm

- Location: Toronto Ontario, Canada

- Contact:

-

Jani Soderhall

- Former ISSA President (2011-2024)

- Posts: 4793

- Joined: Thu Aug 22, 2002 2:00 am

- Location: Sweden, lives in France

- Contact:

SplitFires in stock at ConeRacing.com

Shameless advertising:

SplitFires are now in stock again at ConeRacing.com, so if you're participating at the Paris Slalom World Cup next week get your trucks from our booth.

If you live in Sweden you can get your SplitFires from www.CoyoteBoardStore.se.

/Jani

SplitFires are now in stock again at ConeRacing.com, so if you're participating at the Paris Slalom World Cup next week get your trucks from our booth.

If you live in Sweden you can get your SplitFires from www.CoyoteBoardStore.se.

/Jani

-

Tim Bekmaz

- Posts: 7

- Joined: Tue Dec 20, 2005 9:41 pm

- Location: Orange County California

- Contact:

-

Gary Fluitt

- asphaltplayground.com

- Posts: 328

- Joined: Fri Sep 27, 2002 2:00 am

- Location: Colorado, USA

- Contact:

bottom washers

Wes,

It's a good idea to use a washer down at the bottom if you want the rear steering to be a little more "dead". By eliminating the washer, I find it's a bit more resilient. But not everyone likes a resilient back end (OK, no pun intended). I do not use a washer on the bottom of the front truck either.

I like Ramon's washer idea. No overhang, but a little more base support than no washer.

Gary

It's a good idea to use a washer down at the bottom if you want the rear steering to be a little more "dead". By eliminating the washer, I find it's a bit more resilient. But not everyone likes a resilient back end (OK, no pun intended). I do not use a washer on the bottom of the front truck either.

I like Ramon's washer idea. No overhang, but a little more base support than no washer.

Gary

-

Ramón Königshausen

- Airflow - Skateboards

- Posts: 1485

- Joined: Fri Sep 26, 2003 2:00 am

- Location: Zurich, Switzerland

- Contact:

Just to make it complete

merry x-mas

rmn

Feel the flow – Airflow Skateboards

Real skateboard wheels come in green – ABEC11

Enjoy the ride – GOG Slalom & DH Trucks

Real skateboard wheels come in green – ABEC11

Enjoy the ride – GOG Slalom & DH Trucks

-

Wesley Tucker

- 1961-2013 (RIP)

- Posts: 3279

- Joined: Tue Aug 27, 2002 2:00 am

Bushing Cap For Splitfire?

Gary and Wax,

I still haven't mounted the Splitfires you sent. I'm waiting for the ickMeister to do the VooDoo that he do so well and I'm keeping all this stuff brand new til my new decks are here.

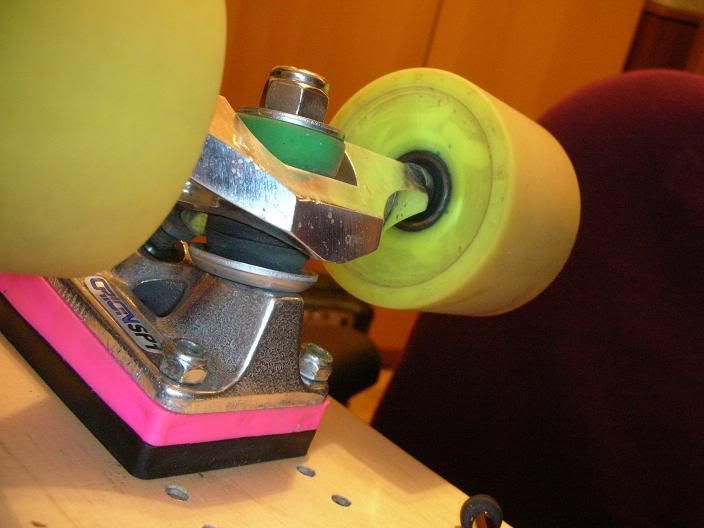

I do, though, have a question. I never noticed before, but this morning I was looking at the hardware and realized the bushing/hangar connection has no cap:

And you can see that a goodly portion of the Khiro bushing is unsupported and kind of "hanging out" in space:

I went ahead and inserted a cap just to see how it would fit and it looks like it was made for a Khiro:

Now the entire bushing is supported.

My immediate gut reaction is this would improve the way the action responds between the bushing and the baseplate. Plus it would extend the life of the bushing as the whole piece is now in action instead of just a portion in the middle. In other words, more even wear.

What do you think? A credible upgrade or just over engineering? I've got a boat load of these caps from other old trucks and doing this is easy. I'd just like to hear if there is a particular reason caps were left off the Randal baseplate or if this little upgrade would have any real appreaciable affect on performance.

Merry Christmas to ya'!

I still haven't mounted the Splitfires you sent. I'm waiting for the ickMeister to do the VooDoo that he do so well and I'm keeping all this stuff brand new til my new decks are here.

I do, though, have a question. I never noticed before, but this morning I was looking at the hardware and realized the bushing/hangar connection has no cap:

And you can see that a goodly portion of the Khiro bushing is unsupported and kind of "hanging out" in space:

I went ahead and inserted a cap just to see how it would fit and it looks like it was made for a Khiro:

Now the entire bushing is supported.

My immediate gut reaction is this would improve the way the action responds between the bushing and the baseplate. Plus it would extend the life of the bushing as the whole piece is now in action instead of just a portion in the middle. In other words, more even wear.

What do you think? A credible upgrade or just over engineering? I've got a boat load of these caps from other old trucks and doing this is easy. I'd just like to hear if there is a particular reason caps were left off the Randal baseplate or if this little upgrade would have any real appreaciable affect on performance.

Merry Christmas to ya'!

-

Ramón Königshausen

- Airflow - Skateboards

- Posts: 1485

- Joined: Fri Sep 26, 2003 2:00 am

- Location: Zurich, Switzerland

- Contact:

If your money is worth it...

What do you want to make more precisely?

The pivot? Your bushings? Your Kingpin? Drillings?

There are only two points on that the hanger touches the baseplate: Pivot and Bushing

How do we solve this "problem" now?

Take a look at a very certain truck....

Of course, this post shall be "a little facetious".

Enjoy experimenting during the offseason

I will look at your news half critically, half curiously.

rmn

What do you want to make more precisely?

The pivot? Your bushings? Your Kingpin? Drillings?

There are only two points on that the hanger touches the baseplate: Pivot and Bushing

How do we solve this "problem" now?

Take a look at a very certain truck....

Of course, this post shall be "a little facetious".

Enjoy experimenting during the offseason

I will look at your news half critically, half curiously.

rmn

Feel the flow – Airflow Skateboards

Real skateboard wheels come in green – ABEC11

Enjoy the ride – GOG Slalom & DH Trucks

Real skateboard wheels come in green – ABEC11

Enjoy the ride – GOG Slalom & DH Trucks

-

Steve Collins

- Harbor Skateboard Racing

- Posts: 358

- Joined: Fri Jan 10, 2003 1:00 am

- Location: Los Angeles

-

Wesley Tucker

- 1961-2013 (RIP)

- Posts: 3279

- Joined: Tue Aug 27, 2002 2:00 am

-

Ramón Königshausen

- Airflow - Skateboards

- Posts: 1485

- Joined: Fri Sep 26, 2003 2:00 am

- Location: Zurich, Switzerland

- Contact:

-

Tod Oles

- Lone Stranger Racing

- Posts: 375

- Joined: Wed Jun 25, 2003 2:00 am

- Location: Blanco, Texas

- Contact:

Gary,

I'd take a couple of baseplates if you decide to do some...

Any idea of the angles you'd be making?? A 60* front and a 30* rear may be nice

as thats close to how they'll get wedged anyway...(well, at least by me)

Also, maybe "slotting" the rear mounting holes just a little bit might be a nice feature

to ease stuffing a long mounting bolt through the deck, fat end of wedge, baseplate combo. I hate fighting that. Especially between heats at a race.....

Hey, JBH

Wasn't the same without you guys in NC.....

And yeah, Greg can even make the slow look like they're in a hurry.....

I think Gary's sandboarding shot and you skating goofy footed are cool shots too...

If you're into that kinda stuff....

Thanks 4 listening, Tod

I'd take a couple of baseplates if you decide to do some...

Any idea of the angles you'd be making?? A 60* front and a 30* rear may be nice

as thats close to how they'll get wedged anyway...(well, at least by me)

Also, maybe "slotting" the rear mounting holes just a little bit might be a nice feature

to ease stuffing a long mounting bolt through the deck, fat end of wedge, baseplate combo. I hate fighting that. Especially between heats at a race.....

Hey, JBH

Wasn't the same without you guys in NC.....

And yeah, Greg can even make the slow look like they're in a hurry.....

I think Gary's sandboarding shot and you skating goofy footed are cool shots too...

If you're into that kinda stuff....

Thanks 4 listening, Tod

avatar by, Greg Fadell

-

Jonathan Harms

- JBH - ISSA Treasurer

- Posts: 890

- Joined: Wed Apr 16, 2003 2:00 am

- Location: St. Louis, MO

-

Gary Fluitt

- asphaltplayground.com

- Posts: 328

- Joined: Fri Sep 27, 2002 2:00 am

- Location: Colorado, USA

- Contact:

Tod,

To machine a high performance base would add probably $70 to the retail cost of the truck. Would you guys be into that? I mean, I'll do it, ifn you guys want them. Doesn't do much to democratize slalom skateboarding, but as long as you guys will line up for a high tech fix, who am I to turn you away....

nice avatar shot by the way....

Gary

To machine a high performance base would add probably $70 to the retail cost of the truck. Would you guys be into that? I mean, I'll do it, ifn you guys want them. Doesn't do much to democratize slalom skateboarding, but as long as you guys will line up for a high tech fix, who am I to turn you away....

nice avatar shot by the way....

Gary

-

Gary Fluitt

- asphaltplayground.com

- Posts: 328

- Joined: Fri Sep 27, 2002 2:00 am

- Location: Colorado, USA

- Contact:

Chris,

The front pivot is meant to be adjustable. You can actually change the angle of the truck a couple of degrees that way. I don't know anyone that can feel 2 degrees of angle change, but hey, maybe my palette is not trained well enough.

Anyway, to lock it down use a nut, and lock tite. I've done this with my trucks and it works great.

Lynn Kramer made a suggestion that we use fine thread pivot bolts for finer adjustment and more secure/solid locking, perhaps with a nylock nut. I am looking into that. Any other suggestions, let me her em'

thanks,

gary

The front pivot is meant to be adjustable. You can actually change the angle of the truck a couple of degrees that way. I don't know anyone that can feel 2 degrees of angle change, but hey, maybe my palette is not trained well enough.

Anyway, to lock it down use a nut, and lock tite. I've done this with my trucks and it works great.

Lynn Kramer made a suggestion that we use fine thread pivot bolts for finer adjustment and more secure/solid locking, perhaps with a nylock nut. I am looking into that. Any other suggestions, let me her em'

thanks,

gary

-

Chris Favero

- CHIxILL Master CFav

- Posts: 504

- Joined: Mon Jun 21, 2004 8:48 pm

- Location: chicago

- Contact:

i am running 90's,in staesville i ran a 30degree base with a blak kihro on the bottom and a red on the top with the wheels all spaced out.i really like these trucks.cf

Freak Bros. Racing

www.chixillskateboards.com

www.chixillskateboards.com

-

Chris Barrett

- Skurfskater

- Posts: 207

- Joined: Thu Feb 17, 2005 5:19 pm

- Location: Toronto Ontario, Canada

- Contact:

hey eddy, you know all the cool kids up here are on the crack todayEddy Martinez wrote:Damm Canadian peer pressure I also broke down and ordered a front Truck off of the Bahne site. Those pics are berry berry sexy. Eddy Texas Outlaws.

I got a question about the 3rd gen; the threaded pivot points, do they come in different sizes or anything? Not a complaint, just a question

-

Tod Oles

- Lone Stranger Racing

- Posts: 375

- Joined: Wed Jun 25, 2003 2:00 am

- Location: Blanco, Texas

- Contact:

Jim, Gary

I tried my new rear Splitfire out for the first time today and I must say, my trusty 30* Seismic has been put up for adoption.

Also,

It was nice of you guys to match my 90mm hanger with a correctly drilled Randal base... (I never knew they came like that.....)

Will we see a matching base soon?

Very nice work! Thank you,

Tod

I tried my new rear Splitfire out for the first time today and I must say, my trusty 30* Seismic has been put up for adoption.

Also,

It was nice of you guys to match my 90mm hanger with a correctly drilled Randal base... (I never knew they came like that.....)

Will we see a matching base soon?

Very nice work! Thank you,

Tod

avatar by, Greg Fadell

-

Jim Weatherwax

- WAX

- Posts: 109

- Joined: Fri Jan 14, 2005 1:20 am

- Location: Northern ColoRado

-

Gary Fluitt

- asphaltplayground.com

- Posts: 328

- Joined: Fri Sep 27, 2002 2:00 am

- Location: Colorado, USA

- Contact:

spaced out

Marion- Not sure whats up with the spacing issue. I'll have another look at the current 107 and see if I can reproduce it. In the meantime, I'll send you some more 5mm spacers.

Gary

Gary

-

Eddy Martinez

- Texas Outlaw

- Posts: 714

- Joined: Thu Oct 24, 2002 2:00 am

- Location: Harlingen, Texas

-

Mike Cividino

- Posts: 289

- Joined: Sat Dec 07, 2002 1:00 am

- Location: Hamilton, Ontario, Canada

-

Marion Karr

- www.downhillbillies.org

- Posts: 405

- Joined: Fri Nov 19, 2004 8:23 pm

- Location: Statesville, North Carolina

- Contact:

Ok...here come's the dumbass newbie question so go ahead and start laughing.....Gary, I finally had time to mount my new Splitfires on my 36" Pocket Pistol Foam Core. (Have not had much time to actually mess with my boards since the Dixie Cup). When I went to install wheels (in this case, cut down Avilas) with the following spacer order from inside to out.....Conical spacer, wheel, speed ring, 10 mm spacer, nut....I did not have enough room to thread the nut on properly. I was not down to the nylon lock threads and the nut easily came off. I tried seating the bearings thinking I had not got them completely inserted in the wheel but this was the case on both sides. (Rear Truck).

Can someone tell me what I am doing wrong? I like the width that the use of the conical spacer inside gave me but there is no way I can ride it with the nut not threading properly.

Any suggestions?

Can someone tell me what I am doing wrong? I like the width that the use of the conical spacer inside gave me but there is no way I can ride it with the nut not threading properly.

Any suggestions?

Marion Karr DHB

DHB WORLD HEADQUARTERS

Sk8sville, North Carolina

HEADBLADE

<br>www.headblade.com

<br>LUCKY 13 TATTOO STUDIO<br>

www.luckythirteentattoo.com<br>

Ninja Bearings

www.skateabsolute.com

DHB WORLD HEADQUARTERS

Sk8sville, North Carolina

HEADBLADE

<br>www.headblade.com

<br>LUCKY 13 TATTOO STUDIO<br>

www.luckythirteentattoo.com<br>

Ninja Bearings

www.skateabsolute.com

-

Steve Collins

- Harbor Skateboard Racing

- Posts: 358

- Joined: Fri Jan 10, 2003 1:00 am

- Location: Los Angeles

-

Miguel Marco

- Posts: 563

- Joined: Wed Aug 17, 2005 10:31 pm

- Location: Quebec, Canada

- Contact:

If it's for big GS offsets, I'd go for -7°. That's what I ran at The Farm Outlaw Finale and was really happy with it's performance. I went to -5° and a smaller wheelbase because the last few sessions were kind of on a tighish hybrid course...Robert Sydia wrote:I think the solution is de-wedging - I will try -5 and see how it performs.

Nothing was wrong with the bushing seats. It's just that the pivot was too short. So it made the hanger "lean" towards the pivot and impeded the bushings from resting flat in the seats. So I had to unscrew the pivot bolt until the bushings were totally flat in the seats and then locked it there with the nut. Does that make any sense???Robert Sydia wrote:What was wrong with the bushing seat????

-

Robert Sydia

- Robert Sydia

- Posts: 179

- Joined: Fri Nov 22, 2002 1:00 am

- Location: Toronto, Canada

Mig:

Thanks for the input - I was running mine flat in the rear and was experiencing a fair amount of slide out, especially in large high speed GS offsets.

I think the solution is de-wedging - I will try -5 and see how it performs.

What was wrong with the bushing seat????

I a currently running my Splitfire with a full green stim bottom, custom lathed green stim on top, flat washers on both ends.

Thanks for the input

All the best

Rob

Thanks for the input - I was running mine flat in the rear and was experiencing a fair amount of slide out, especially in large high speed GS offsets.

I think the solution is de-wedging - I will try -5 and see how it performs.

What was wrong with the bushing seat????

I a currently running my Splitfire with a full green stim bottom, custom lathed green stim on top, flat washers on both ends.

Thanks for the input

All the best

Rob

-

Miguel Marco

- Posts: 563

- Joined: Wed Aug 17, 2005 10:31 pm

- Location: Quebec, Canada

- Contact:

Mine works great now, after a bit of tinkering. I have it setup with medium green Stimulator on the bottom without washer, top JimZ on the top with inverted small cup washer. Felt a bit weird at first, then I noticed that the bushings were popping out of the seats! I had to lengthen the pivot screw and lock it with the bolt to keep the bushings in place. May try a bottom JimZ on the top to see if I can get even more acceleration out of the turns, if the snow melts for a couple of days before we really get buried for the winter...Robert Sydia wrote:Mig:

How do you have your rear split fire set-up?

I have one installed on my GS board and do not seem to have it dialed in yet.

Any insight and/or advice would be greatly appreciated.

All the best

Rob

I ran it with -8° wedge at first. Ended up wanting a little bit more turn from the back with my current setup(*) so I traded the Khiro wedge rail stacks for a hard plastic wedge (probably around -5° now).

But one thing is a big let down for me. When I dissassembled the hanger to take care of the bushing seats problem after my first session, I checked it's straightness and was really disappointed. I can't imagine how well it would perform if it was truly straight!

(*) Skaterbuilt CK GS, MMW RTX team truck on the front with bottom JimZ bushing on the bottom with inverted small cup washer and lathed medium green Stim on the top with flat washer, 7° wedge.

-

Ron Barbagallo

- Fatboy

- Posts: 757

- Joined: Fri Mar 05, 2004 3:23 pm

- Location: Jersey

- Contact:

-

Robert Sydia

- Robert Sydia

- Posts: 179

- Joined: Fri Nov 22, 2002 1:00 am

- Location: Toronto, Canada

-

Miguel Marco

- Posts: 563

- Joined: Wed Aug 17, 2005 10:31 pm

- Location: Quebec, Canada

- Contact:

-

Mike Cividino

- Posts: 289

- Joined: Sat Dec 07, 2002 1:00 am

- Location: Hamilton, Ontario, Canada

-

Miguel Marco

- Posts: 563

- Joined: Wed Aug 17, 2005 10:31 pm

- Location: Quebec, Canada

- Contact:

Re: 3s

Does this new feature rule out the use of bushings like the Stimulators or JimZ's? I'm running a rear Phase II with a bottom Stim and top JimZ and wouldn't trade that combo for anything. I was planning on buying a pair of Phase III's but if those bushings don't fit, I'll start looking for used Phase II's...Gary Fluitt wrote:Additionally I've made the bushing seats deeper so that the bushings will stay in place better. You can see that a khiro bushing fits deeply into the bushing socket now almost up to the screened lettering on the bushing...

And thanks Paul for all those tips...

-

Paul Howard

- Posts: 202

- Joined: Sat Dec 27, 2003 7:15 pm

- Location: Corvallis, Oregon. USA

Tip for Conical Spacers for Splitfires

Hey, here's what I do:

1) Go to a bike shop, take your hanger and the Asphalt Playground conical spacers with you.

2) Show the bike shop person your hanger and tell them you need a spacer that will fit OVER the bearing shoulder so you have a better bigger base for the conical spacer to bear it's compression load against.

****NOTE**** The Phase I Splitfire had a bearing shoulder that matched perfectly with spacer ring washers from bike shops (I don't remember the exact thickness or inner hole diameter). HOWEVER, the Phase III bearing shoulder sticks out farther and flares slightly as it projects away from the hanger toward the axle tip and thus has a slightly larger diameter than the bearing shoulder compared to the Phase I bearing shoulder.

If you can't find a spacer ring that fits around it, a smidgeon of careful filing with a metal file around the bearing shoulder cicumferentially will solve that issue. ALSO, the Phase III bearing shoulder projects out farther so you might need to use 2 spacer rings to fill that gap so the AP conical spacer ring has a solid seat.

3) After you have obtained bike spacer rings that fit(or used a file on the Splitfire bearing shoulders to reduce their diameter to get them to fit), put them on the hanger over the bearing shoulders and put the Asphalt Playground conical spacer ring on the axle next to the bike spacer ring. Now you will have a really nice solid base to support the leverage load on your axles from riding with your hanger spaced out(assuming you have the axle nuts tightened down snug).

I ride Grippins a lot, and I like a little wider hanger width than most peaple so I only use the conical spacers "inside" the wheels next to the hanger and the extra bearing spacer "outside" the wheel next to the nut. This is because I'm paranoid and feel that extending much more than the amount of the conical spacer is sort of a bad practice in terms of straining the axles. I use this setup for tight and hybrid courses with Grippins. This will put your wheels almost exactly even with riding with Avalons or Manx without the spacers.

For G/S riding with Avalons, Avila's, Manx, or Gumballs, this method will work great if you want that little bit more hanger width for a bigger faster course.

More Deep Thoughts:

I applaud Gary and Wax for using overly-long semi-axles installed into the Splitfire hanger for the reason that if the bearings (even with the conical spacer in use) are completely supported by non-threaded clean axle within them, the wheel alignment will be a smidge better with less wiggle room also, and by requiring a spacer between the wheel and the axle nut, that will help with perpendicular loading of stress on the bearing even if the nut is not perfectly true.

Using Wallgren style "Monkey Nuts" to me is always a good idea whether you get them from Wallgren or do it yourself with an electric drill and a file.

Plus JBH's precicion Machinist made bearing spacers really work.

How the Phase II's fit into all of this , I don't know but I'm sure all of the above is applicable.

Well, I thought this would be a lot shorter than what I just wrote. Good Luck-Paul

1) Go to a bike shop, take your hanger and the Asphalt Playground conical spacers with you.

2) Show the bike shop person your hanger and tell them you need a spacer that will fit OVER the bearing shoulder so you have a better bigger base for the conical spacer to bear it's compression load against.

****NOTE**** The Phase I Splitfire had a bearing shoulder that matched perfectly with spacer ring washers from bike shops (I don't remember the exact thickness or inner hole diameter). HOWEVER, the Phase III bearing shoulder sticks out farther and flares slightly as it projects away from the hanger toward the axle tip and thus has a slightly larger diameter than the bearing shoulder compared to the Phase I bearing shoulder.

If you can't find a spacer ring that fits around it, a smidgeon of careful filing with a metal file around the bearing shoulder cicumferentially will solve that issue. ALSO, the Phase III bearing shoulder projects out farther so you might need to use 2 spacer rings to fill that gap so the AP conical spacer ring has a solid seat.

3) After you have obtained bike spacer rings that fit(or used a file on the Splitfire bearing shoulders to reduce their diameter to get them to fit), put them on the hanger over the bearing shoulders and put the Asphalt Playground conical spacer ring on the axle next to the bike spacer ring. Now you will have a really nice solid base to support the leverage load on your axles from riding with your hanger spaced out(assuming you have the axle nuts tightened down snug).

I ride Grippins a lot, and I like a little wider hanger width than most peaple so I only use the conical spacers "inside" the wheels next to the hanger and the extra bearing spacer "outside" the wheel next to the nut. This is because I'm paranoid and feel that extending much more than the amount of the conical spacer is sort of a bad practice in terms of straining the axles. I use this setup for tight and hybrid courses with Grippins. This will put your wheels almost exactly even with riding with Avalons or Manx without the spacers.

For G/S riding with Avalons, Avila's, Manx, or Gumballs, this method will work great if you want that little bit more hanger width for a bigger faster course.

More Deep Thoughts:

I applaud Gary and Wax for using overly-long semi-axles installed into the Splitfire hanger for the reason that if the bearings (even with the conical spacer in use) are completely supported by non-threaded clean axle within them, the wheel alignment will be a smidge better with less wiggle room also, and by requiring a spacer between the wheel and the axle nut, that will help with perpendicular loading of stress on the bearing even if the nut is not perfectly true.

Using Wallgren style "Monkey Nuts" to me is always a good idea whether you get them from Wallgren or do it yourself with an electric drill and a file.

Plus JBH's precicion Machinist made bearing spacers really work.

How the Phase II's fit into all of this , I don't know but I'm sure all of the above is applicable.

Well, I thought this would be a lot shorter than what I just wrote. Good Luck-Paul

I just dig slalom!

-

Steve Collins

- Harbor Skateboard Racing

- Posts: 358

- Joined: Fri Jan 10, 2003 1:00 am

- Location: Los Angeles

schplit fahr

I agree, the pivot refinement is an aesthetic improvement as well.

Now when is somebody going to produce RII-replacement precision baseplates (please)?

Now when is somebody going to produce RII-replacement precision baseplates (please)?

-

Martin Drayton

- Gecko Decks

- Posts: 732

- Joined: Mon Sep 02, 2002 2:00 am

- Location: Park City,Utah!

- Contact:

You got a purty truck...

Gets better every time! I've said it once and I'll say it again...the easiest high performance truck to get used to AND the best value! Its also damned sexy looking too...

http://www.geckodecks.com

Seismic.

Khiro /NITRO Bearings,

Decent Hardware

http://www.headblade.com/Merchant2/merc ... IL=drayton

-

Gary Fluitt

- asphaltplayground.com

- Posts: 328

- Joined: Fri Sep 27, 2002 2:00 am

- Location: Colorado, USA

- Contact:

3s

steve - the geometry (35 rear and 50 front) are unchanged, and the hanger widths (90mm and 107mm) are the same in rev3. The change is in the profile of the pivot bolt area. We took this down quite a bit to lighten it up. You can see that in the photo below...<br><center>

<img src="http://asphaltplayground.com/images/vie ... r></center>

Additionally I've made the bushing seats deeper so that the bushings will stay in place better. You can see that a khiro bushing fits deeply into the bushing socket now almost up to the screened lettering on the bushing...<br><center>

<img src="http://asphaltplayground.com/images/vie ... r></center>

lastly, the bearing shoulder on the side of the hanger is a bit more raised, about 2mm. I suppose if there were someone out there that HAD to have an 86mm split, they could simply grind off the bearing shoulders. You'd still want to run speed washers on the inside of the wheel. <br><center>

<img src="http://asphaltplayground.com/images/view1.jpg">

<img src="http://asphaltplayground.com/images/vie ... r></center>

Additionally I've made the bushing seats deeper so that the bushings will stay in place better. You can see that a khiro bushing fits deeply into the bushing socket now almost up to the screened lettering on the bushing...<br><center>

<img src="http://asphaltplayground.com/images/vie ... r></center>

lastly, the bearing shoulder on the side of the hanger is a bit more raised, about 2mm. I suppose if there were someone out there that HAD to have an 86mm split, they could simply grind off the bearing shoulders. You'd still want to run speed washers on the inside of the wheel. <br><center>

<img src="http://asphaltplayground.com/images/view1.jpg">

-

Steve Collins

- Harbor Skateboard Racing

- Posts: 358

- Joined: Fri Jan 10, 2003 1:00 am

- Location: Los Angeles

-

Robert Sydia

- Robert Sydia

- Posts: 179

- Joined: Fri Nov 22, 2002 1:00 am

- Location: Toronto, Canada

SEXY, SEXY, SEXY

Those are incredibly SEXY

Excellent work to all those involved

Rob

Excellent work to all those involved

Rob

-

Leonardo Ojeda

- Venezuelan Racer

- Posts: 286

- Joined: Sat Sep 14, 2002 2:00 am

- Location: Stamford, CT and Venezuela in the heart

- Contact:

-

Wesley Tucker

- 1961-2013 (RIP)

- Posts: 3279

- Joined: Tue Aug 27, 2002 2:00 am

-

Adam Daniels

- Adam Daniels

- Posts: 305

- Joined: Thu May 26, 2005 11:08 pm

- Location: Albany, New York

- Contact:

-

Wesley Tucker

- 1961-2013 (RIP)

- Posts: 3279

- Joined: Tue Aug 27, 2002 2:00 am

Gary,

Nope. I'll have to admit it was the one-speed-ring/conical spacer combination that confused me the most. Of course, feel free to post pics here for a reference to anyone else who has the same questions when they pull their Splits out of the box for the first time.

Fortunately for all of us, this note from you will always be available on SS.com and easily referred to in the future.

When the Icks get here and I start with the screwdriver and socket wrench, I'll come back to this to keep everything straight.

Thanks.

Nope. I'll have to admit it was the one-speed-ring/conical spacer combination that confused me the most. Of course, feel free to post pics here for a reference to anyone else who has the same questions when they pull their Splits out of the box for the first time.

Fortunately for all of us, this note from you will always be available on SS.com and easily referred to in the future.

When the Icks get here and I start with the screwdriver and socket wrench, I'll come back to this to keep everything straight.

Thanks.

-

Gary Fluitt

- asphaltplayground.com

- Posts: 328

- Joined: Fri Sep 27, 2002 2:00 am

- Location: Colorado, USA

- Contact:

spaced out

Wes. It's a puzzle, if I give you the answer where is the fun in that?

The axles on the new Splitfire are generous. So generous in fact that if you slam a wheel on the axles you will still have bare axle hanging out on the outside of the bearing before you get to the threads. So if you are running the truck in it's narrow-est configuration (90mm or 107mm) there will be some axle to suck up on the outside of the wheel. In this case, use the 10mm spacer on the outside of the wheel.

If you want to run the truck a little wider, say 10mm wider, so 100mm or 117mm, put the conical 5mm aluminum spacers on first, then wheel, then the 10mm spacer. face the coned sider of the spacer toward the bearing shield.

If your feeling ghetto and you want to run your truck w i d e, slap the 10mm spacer on first, then wheel, then the 5mm spacer.

Finally, the speed ring is only necessary on the outside of the wheel, if you were running the truck super wide, like J-Lo wide, with the 10mm AND the 5mm on the inside of the wheel for what would be 120mm and 137mm effective hanger width. I've not done this, cause I never run that wide a hanger, even in Super G. And I don't like putting my wheels that far away from the hanger, though I'm sure the axles would have no problem running them that way.

Would pictures be useful?

The axles on the new Splitfire are generous. So generous in fact that if you slam a wheel on the axles you will still have bare axle hanging out on the outside of the bearing before you get to the threads. So if you are running the truck in it's narrow-est configuration (90mm or 107mm) there will be some axle to suck up on the outside of the wheel. In this case, use the 10mm spacer on the outside of the wheel.

If you want to run the truck a little wider, say 10mm wider, so 100mm or 117mm, put the conical 5mm aluminum spacers on first, then wheel, then the 10mm spacer. face the coned sider of the spacer toward the bearing shield.

If your feeling ghetto and you want to run your truck w i d e, slap the 10mm spacer on first, then wheel, then the 5mm spacer.

Finally, the speed ring is only necessary on the outside of the wheel, if you were running the truck super wide, like J-Lo wide, with the 10mm AND the 5mm on the inside of the wheel for what would be 120mm and 137mm effective hanger width. I've not done this, cause I never run that wide a hanger, even in Super G. And I don't like putting my wheels that far away from the hanger, though I'm sure the axles would have no problem running them that way.

Would pictures be useful?

-

Wesley Tucker

- 1961-2013 (RIP)

- Posts: 3279

- Joined: Tue Aug 27, 2002 2:00 am

Spacers and what do to next?

Gary,

OK. We're stumped.

I received my Splitfires today and have one question: in what order to you install the wheel and spacers?

The truck comes with THREE AXLE ADD-ONS: A wide spacer, ONE speed ring and this strange-looking, never before seen conical-ended thin spacer.

So what's what and what's the deal with this strange conical spacer? Any advice or direction would be appreciated. (By the way, I talked with Marion today and he's as equally mystified. That makes me feel better. At least I'm not the only guy in the dark on all this!)

Thanks.

P.S. Nice looking piece of machinery. And great delivery service. Keep up the good work!

OK. We're stumped.

I received my Splitfires today and have one question: in what order to you install the wheel and spacers?

The truck comes with THREE AXLE ADD-ONS: A wide spacer, ONE speed ring and this strange-looking, never before seen conical-ended thin spacer.

So what's what and what's the deal with this strange conical spacer? Any advice or direction would be appreciated. (By the way, I talked with Marion today and he's as equally mystified. That makes me feel better. At least I'm not the only guy in the dark on all this!)

Thanks.

P.S. Nice looking piece of machinery. And great delivery service. Keep up the good work!

-

Gary Fluitt

- asphaltplayground.com

- Posts: 328

- Joined: Fri Sep 27, 2002 2:00 am

- Location: Colorado, USA

- Contact:

uncovered

no body, no grave. A connection to the Columbians, witness protection. Resurfaces on the East Coast under an alleged name. WHO still stands on a skateboard like that? Brewington's height eliminates him from get go. It's all there, plain as day.

-

Marty Schaub

- Old LaCosta Boy

- Posts: 523

- Joined: Thu Feb 10, 2005 5:43 pm

- Location: Dacula, JoJa

Piercy re-born?

About the time Piercy dies, Tucker emerges......

HMMMMM, Gary I think your on to something here.........

HMMMMM, Gary I think your on to something here.........

La Costa Boy For Life