Timing System

Moderator: Jani Soderhall

-

Wesley Tucker

- 1961-2013 (RIP)

- Posts: 3279

- Joined: Tue Aug 27, 2002 2:00 am

Post

by Wesley Tucker » Wed Jun 24, 2009 4:54 pm

Peter,

Two things.

One: tapeswitches must ALWAYS be stored flat. Some people roll them up but that's still an invitation to crimp the metal. If you laid one down and didn't tape then probably that allowed a wheel to crunch the switch instead of roll over it.

Two: building a tapeswitch type mechanism is really not feasible. It's been tried.

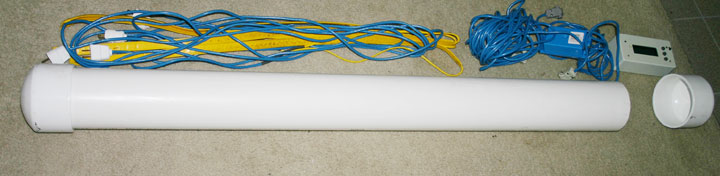

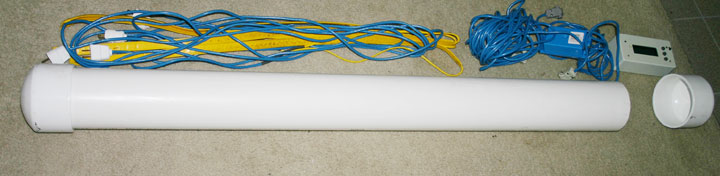

What I would suggest is take the plunge, buy new strips and invest in a storage case that can be used to keep the strips flat. What I did was went to a home store and bought a length of 12-cm (5 inch) plastic pipe and two end caps. I cut the pipe at about 4.5 feet in length. I slide all the switches in flat and have enough room to also put in the connecting wires. A 5-inch tube is also wide enough to hold the TrakMate timer. Everything all in one container and the switches won't get crimped. That plus my cable spool is my timer.

-

Peter Harnischmacher

- prikelpit

- Posts: 49

- Joined: Wed Apr 16, 2008 6:24 am

- Location: Berlin west sure

Post

by Peter Harnischmacher » Wed Jun 24, 2009 4:09 pm

@jani:

continuous contact...Perhaps because we used it without tape for one time?

@Pat

I built my own, but they were less reliable than

yes I thought that, because nobody wrote something about DIY switches!

Thx for answer prikel

-

Jani Soderhall

- Former ISSA President (2011-2024)

- Posts: 4789

- Joined: Thu Aug 22, 2002 2:00 am

- Location: Sweden, lives in France

-

Contact:

Post

by Jani Soderhall » Mon Jun 22, 2009 9:40 pm

What's the problem?

/Jani

-

Peter Harnischmacher

- prikelpit

- Posts: 49

- Joined: Wed Apr 16, 2008 6:24 am

- Location: Berlin west sure

Post

by Peter Harnischmacher » Mon Jun 22, 2009 7:48 pm

...shitty tapeswitch! Has anyone ever even built? It is not about the price but the shelf!

For tips and suggestions always happy!

cheers prikel